|

|

Determination of stress

This is the area of activity to which the laboratory devoted most of its attention and efforts in the past ten years. The technique it has developed permits to monitor stresses produced in the structures of ropeway installations under different conditions of load and speed and to monitor stresses both in the laboratory and in the field on ropeway  installations that are being operated. The objective aimed at was a method of determination permitting to compare design stresses with real stresses and thus have an element of reference permitting to assess the extent to which assumed design loads are permissible and acceptable. Static tests are carried out in the laboratory with increasing loads of the carrier up to a load corresponding to twice the nominal load. This series of tests is usually carried out with new carriers or in the event of important alterations of existing carriers. installations that are being operated. The objective aimed at was a method of determination permitting to compare design stresses with real stresses and thus have an element of reference permitting to assess the extent to which assumed design loads are permissible and acceptable. Static tests are carried out in the laboratory with increasing loads of the carrier up to a load corresponding to twice the nominal load. This series of tests is usually carried out with new carriers or in the event of important alterations of existing carriers.

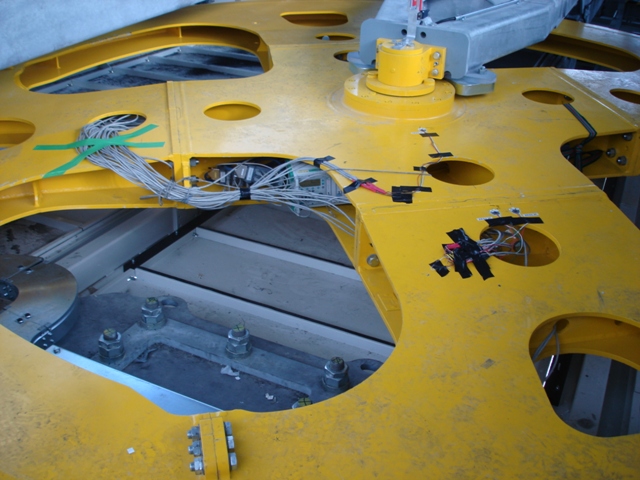

The results of these preliminary tests show up the alterations of the carrier design that need to be made prior to its release for the production of big series. Real stresses are measured in the most significant points of the structure of the carrier and of the grip. These measurements are carried out on completed installations under dynamic test conditions.

Readings corresponding to different load and speed conditions are taken along the whole length of the line, while the carrier is passing over the line support structures or entering into the station, where the dynamic effect is greatest. Under the regulations established by the supervisory authorities this test has to be carried out for all new projects of detachable grip ropeways (4S and 6S chairlifts, gondolas) as well as new projects of conventional ropeways and funiculars.

A point to be stressed is the significant development of the instrumentation, both in terms of quantity, i.e. the number of sensors used, as well as in terms of ease of handling when measurements have to be carried out in difficult environmental conditions or in places with limited space for movements. The switch board of the laboratory can handle 48 dynamic channels.

The data acquisition system of the installation has been devised for simultaneous storage in a standalone unit of signals sent by 16 sensors. Data can be transferred any time to a Memory Card and processed by the central unit of the head office. Data can also be transmitted via radio which means, that the operator can attend to the test which is carried out in the station and acquire data in real time. If the layout of the line is such that no radio transmission is possible, the operator with the receiver travels on the carrier that immediately follows. The data acquisition system of the installation has been devised for simultaneous storage in a standalone unit of signals sent by 16 sensors. Data can be transferred any time to a Memory Card and processed by the central unit of the head office. Data can also be transmitted via radio which means, that the operator can attend to the test which is carried out in the station and acquire data in real time. If the layout of the line is such that no radio transmission is possible, the operator with the receiver travels on the carrier that immediately follows.

Inspection of grips, i.e. the component of a carrier that comes into contact with the structures of the station when the carrier enters the station, is given topmost attention. Next to stresses produced by the clamping force the rope has to withstand additional stresses produced by the impact of grips against the structures. If this combination of stresses sum up to an excessive stress, the manufacturer can modify the structure or adjustment of entrance guides, or modify the carrier by adding shock absorbers. Such alterations may bring about a twofold advantage : a purely technical improvement and improved travel comfort, which no doubt is highly appreciated by the user of the installation.

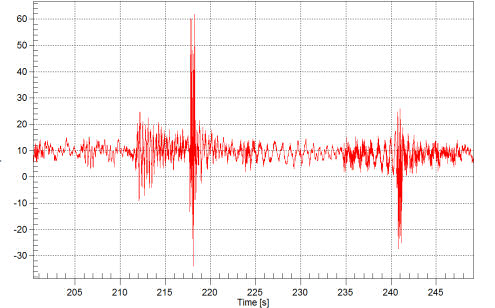

The recording apparatus delivers flow diagrams of stresses produced in different points of the structure thus showing details that need to be changed and supplying an information on the effect of such alterations. Measures are also taken with intentionally swung out carriers.

Seen the high number of standard test procedures that have been carried out in the last years the laboratory was in the position to collect sufficient data to draw up statistical surveys the results of which were reported to international conferences. The same procedures has been also used to collect data for other transport systems and branches of mechanical engineering (construction of machines, containers, tanks etc.)

|

|

|